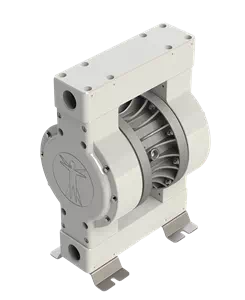

Double Diaphragm Pump

Diaphragm Pump หรือ Air Operated Diaphragm Pump (AODD Pump)

ปั๊มสารเคมี ใช้ในการสูบจ่ายของเหลว ที่มีส่วนผสมของสารเคมีและต้องเจอปัญหาการกัดกร่อน. Argal จึงได้ผลิตปั๊มลม หรือ Double Diaphragm Pump ขึ้นมาเพื่อตอบสนองกลุ่มลูกค้าที่ต้องการนำไปใช้ในงานสูบจ่ายสารเคมี ใช้งานในบริเวณที่ไม่มีไฟฟ้าใช้ ใช้ได้ดีกับสารเคมีและในสภาวะแวดล้อมการทำงานที่สุ่มเสี่ยงต่อการระเบิด ข้อดีของ Diaphragm Pump ของ Argal ก็คือสามารถเคลื่อนย้ายโดยง่าย การติดตั้งไม่ยุ่งยาก

Diaphragm Pump มักใช้ในหลายอุตสาหกรรม เช่น อุตสาหกรรมเคมี การบำบัดน้ำเสีย การขนส่งน้ำมัน หรือการทำอาหาร เนื่องจากความยืดหยุ่นในการใช้งานและความสามารถในการทำงานกับของเหลวหลากหลายชนิด

เนื่องด้วยขนาดและวัสดุที่น้ำหนักเบา มีวัสดุให้เลือก เช่น GFR-PP, CFF-PVDF, PVDF, SUS 316, Aluminum, SUS 316 Polished, PTFE, Santoprene and Keyflex ใช้แรงดันของลมในการขับเคลื่อนการทำงาน ทำให้การใช้งานและทั้งบำรุงรักษาทำได้ง่าย นอกจากนี้ Argal Pump มีปั๊มให้เลือกหลายแบบ ทั้ง AODD Pump, Centrifugal Pump, Self Priming Pump, Fiberglass Pump, Vertical Pump.

คุณสมบัติเด่นของ Diaphragm Pump

Argal Astrasolid DDS

- ประสิทธิภาพสูงมาก

- การใช้ลมที่ได้รับการปรับปรุงให้มีประสิทธิภาพ

- ฝาปิดผ้าใบที่พัฒนาขึ้น

- ระบบ Free-ice ที่ช่วยเพิ่มประสิทธิภาพและยังคงการใช้ลมให้น้อย

- การออกแบบภายในที่ได้รับการปรับปรุงเพื่อช่วยในการถ่ายโอนของเหลวที่มีความหนืดและมีประจุ

- ตัวแลกเปลี่ยนลมที่รวดเร็วมาก

- ความไวในการทำงานที่ได้รับการปรับปรุง (จาก 1 บาร์)

- ป้องกันการหยุดชะงัก

- PE1000: วัสดุที่มีความต้านทานสูง มีสัมประสิทธิ์การเสียดทานต่ำและช่วงอุณหภูมิจาก -40°C ถึง 70°C

- ผ้าใบ TFM ที่ไม่ทำปฏิกิริยากับสารเคมี

- ผ้าใบมีให้เลือกในวัสดุยางเทอร์โมพลาสติก (TPE, TPV) และยางยืดที่เสริมแรง (FKM, EPDM, NBR)

- ประสิทธิภาพสูงมาก

- บำรุงรักษาง่าย

- เหมาะสำหรับของเหลวที่ไวต่อการตัด (shear sensitive liquids)

- การทำงานโดยไม่ต้องใช้น้ำหล่อเย็น (Dry-running)

- สามารถดูดน้ำเองได้ (Self-priming)

- ATEX Zona 2 (Serie II 3/3/ IIB T4)

Model DDS 30

สเปคสินค้า

- Fluid connections: 1/2 BSP

- Air connections: 6 mm

- Max flow rate: 52 l/m

- Max air pressure: 8 bar

- Displacement/cycle: 70

- Max size solids: 3mm

Model DDS 100

สเปคสินค้า

- Fluid connections: 1/2" BSP, NPT, Flanged DNS

- Air connections: 3/8" BSP, NPT

- Max flow rate: 130 l/m

- Max air pressure: 8 bar

- Displacement/cycle: 240

- Max size solids: 5.5 mm

Model DDS 400

สเปคสินค้า

- Fluid Connections: Flanged DN40, 1 ½" BSP, NPT

- Air connections: ½" BSP, NPT

- Max flow rate: 375 l/m

- Max air pressure: 8 bar

- Diaplacement/cycle: 1.340

- Max size solids: 7 mm

Model DDS 650

สเปคสินค้า

- Fluid Connections: Flanged DN50, 2, BSP, NPT

- Air connections: ¾", BSP, NPT

- Max flow rate: 715 l/m

- Max air pressure: 8 bar

- Diaplacement/cycle: 3.820

- Max size solids: 9 mm

ติดต่อฝ่าขาย

02-274-5214