Pump Bearing

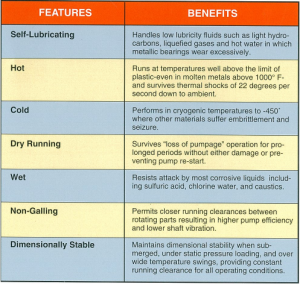

GraphAlloy เป็นผู้ผลิตแบริ่ง หรือ บุชชิ่ง ที่มีสารหล่อลื่นในตัว (Self-Lubricate Bearing) ใช้สำหรับทดแทนเป็นแบริ่ง หรือปั๊ม มีคุณสมบัติ หล่อลื่นในตัวไม่ต้องใช้นำมันหล่อลื่น ทนต่อการกัดกร่อน ขีดข่วน ทนอุณหูมิได้เกิน 1000°F ใช้สำหรับงานที่อาจจะเกิดการ Run Dry ของปั๊ม, ปั๊มที่เกิดปัญหาเปิดปิดบ่อยๆ GraphAlloy จะช่วยทำให้การเดินเครื่องทำได้อย่างต่อเนื่อง ไม่มีความเสียหาย ค่าบำรุงรักษาต่ำ

GraphAlloy, graphite/metal alloy is a seft-lubricating bearing material used by designers and maintenance engineers to solve the toughest pump applications-from new installations to retrofitting existing units.

GraphAlloy is non-galling, corrosion resistant, dimensionally stable and performs at temperatures from cryogenic to higher than 1000°F.,

GraphAlloy allows pumps to survive "run dry" conditions, slow roll operation and frequent stops/starts where metal and plastics fail. GraphAlloy works in low lubricity, corrosive and sour liquids. The use of GraphAlloy pump wear parts result i lower operating and repair costs and provides assurance against catastrophic failures.

ข้อดีของ Pump Bearing

GraphAlloy Reduce Vibration

Pumps with mechanical seals have frequent failures due to excessive shaft vibration. Upgrades using GraphAlloy case rings and close clearance throat bushings provide reduced vibration levels-in one specific case and bearing failures and increased MTBF.

This upgrade is recongnized in the current API 682 standard. GraphAlloy more than meets this specification.

GraphAlloy Extends Life for Continuous Service

Self-lubricating GraphAlloy has long been the standard bearing in vertical "can" pumps in the refinery tank farm area. The typical light dydrocarbon products have poor lubricity and tendency to "flash". This, combined withrecurring "run dry" operation when the tanks emptied, motivated designed and operaators to search for a replacement of the bronze bearing material. GraphAlloy is now the overwhelming choise (confirmed by the API 610 Eightnh Edition) for lower wear rates and "run dry survival."

GraphAlloy Permits Dry Starts

Deep setting vertical turbine well pumps require pre-lubrication of the standard bronze or rubber bearings between the low water levels and the discharge surface. Environmental concerns have now restricted the use of oil and grease.

The alternate of water from a local source for start-up requires a complicated auxiliary system. The solutions is to use GraphAlloy lineshaft bushings which eliminate the need for any pre-lubrication by running dry unitil pump discharge flow is established.

At one installation, the engineer estimated that it would take more than five minutes for the pumpage to reach the surface discharge from lower water level. GraphAlloy survived this duration with margin to spare.