Submersible Mixer

Faggiolati submersible mixer provide mixing or agitating or harmonizing of fluid in tank or pond in waste water system or any mixing requirements

Faggiolati's mixers are projected for optimal mixing, homogenising and agitating operations in civil and industrial waste-water purification plants. The high performance ratings allow a considerable reduction in running costs. The non-clogging propeller profile, combined with an accurate projection, guarantees optimal running condictions with absolute reliability.

Applications

Thanks to their versatility, Faggiolati's mixers can be used in a wide range of applications. The combination of various construction materials, the stainless steel propellers and bouble silicon carbide mechanical seals allow the use of these mixers in highly corrosive conditions and at high temperatures.

Typical applications for these types of mixer are: - homogenisation of heavy sludge or liquids with solid particles - Removal of sedymentary deposits. - to avoid ice formation.

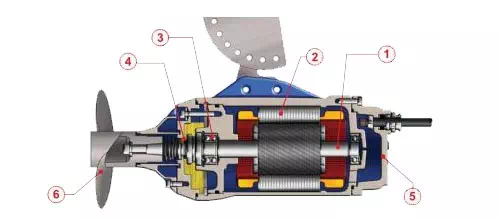

Submersible Mixer Series GM17

∅ 170 mm

- Shaft realized in stainless steel AISI420

- Motor asynchronous threephase 4 poles, insulation class H(180°C)

- Upper seal: ceramic/graphite

- Lower seal: silicon carbide/silicon carbide

- Hosing: Cast Iron EN-GJL-250

- Propeller: Stainless steel AISI316

Specification

- Code: 6001408

- Type: GM17A471T1-4V2KA0

- Absorbed power P1 (kW): 0,6

- Propeller diameter (mm): 176

- Thrust (N): 120

- Weight (Kg): 20

- Motor rated: 1352 (RPM), 0,7 (Power kW), 1,5 (Current A)

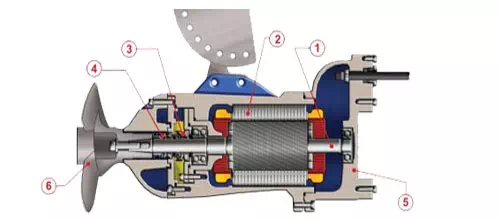

Submersible Mixer Series GM18 1

∅ 180 mm

- Shaft realized in stainless steel AISI420

- Motor asynchronous threephase 4 poles, insulation class H(180°C)

- Upper seal: ceramic/graphite

- Lower seal: silicon carbide/silicon carbide

- Hosing: Cast Iron EN-GJL-250

- Propeller: Stainless steel AISI316

Specification

- Code: 6001412

- Type: GM18B471T1-4V2KA0

- Absorbed power P1 (kW): 1,2

- Propeller diameter (mm): 191

- Thrust (N): 220

- Weight (Kg): 30

- Motor Rated: 1382 (RPM), 1,4 (Power kW), 2,7 (Current A)

- Code: 6008138

- Type: GM18B471T1-4W2KA0

- Absorbed power P1 (kW): 0,9

- Propeller diameter (mm): 191

- Thrust (N): 170

- Weight (Kg): 33

- Motor Rated: 1352 (RPM), 1,1 (Power kW), 2,4 (Current A)

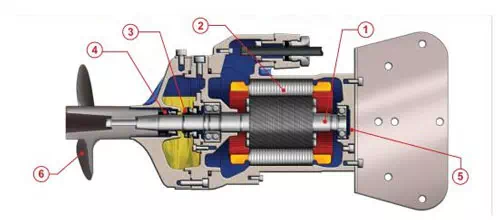

Submersible Mixer Series GM19

∅ 190 mm

- Shaft realized in stainless steel AISI420

- Motor asynchronous threephase 4 poles, insulation class H(180°C)

- Upper seal: ceramic/graphite

- Lower seal: silicon carbide/silicon carbide

- Hosing: Cast Iron EN-GJL-250

- Propeller: Stainless steel AISI316

Specification

- Code: 6007801

- Type: GM19B409T1-4T6KA0

- Absorbed power P1 (kW): 1,7

- Propeller diameter (mm): 197

- Thrust (N): 275

- Weight (Kg): 40

- Motor Rated: 1382 (RPM), 2,3 (Power kW), 4,4 (Current A)

- Code: 6008789

- Type: GM19B409T1-4C6KA0

- Absorbed power P1 (kW): 1,2

- Propeller diameter (mm): 197

- Thrust (N): 220

- Weight (Kg): 43

- Motor Rated: 1382 (RPM), 1,5 (Power kW), 2,9 (Current A)