Clutch

CECON Clutches

Marland เป็นผู้ผลิต Clutches ชนิดออกแบบทนทานเป็นพิเศษ ใช้เมื่อเกินความเร็วเกินของระบบคลัทช์ธรรมดา ใช้อย่างต่อเนื่อง ใช้ในบริเวณที่สิ่งแวดล้อมเลวร้าย เช่น มีผุ่น, เปียกชื้น, กลางแจ้ง, อุณหูมิสูง และแกนของตัวขับและตัวถูกขับไม่อยู่ในแนวราบ

Marland CECON Clutches are designed for applications where one or more of the following conditions exists.

- Shaft speeds exceeds the permissible maximum for standard clutches, clutch couplings, or backstops.

- Uninterrupted, continuous operation is required.

- Operation under extremely wet, dusty, abrasive, or other adverse atmospheric conditions; or on unprotected outdoor applications;

or subject to high ambient temperatures. - Shaft axis is not horizontal, as on cement kiln drives.

- Lubrication maintenance must be provided on a no “down-time” basis.

Design Feature

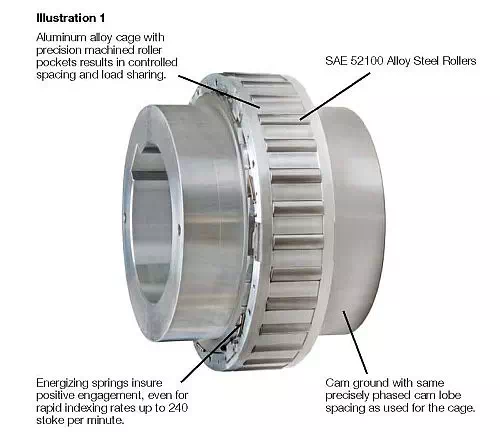

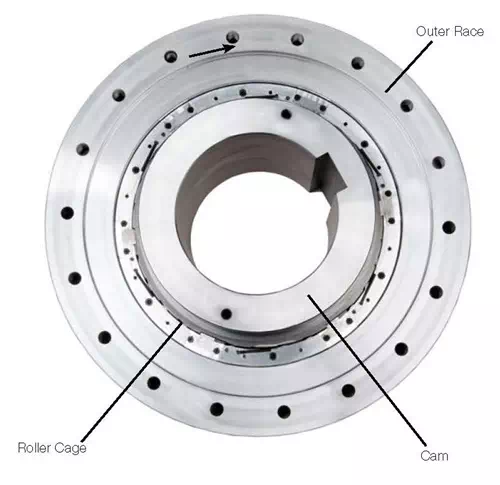

The basic clutch elements of cam, roller cage and outer race are similar items as employed for other Marland Clutches. In addition, CECON Clutches are designed to keep freewheeling clutch parts and bearings adequately lubricated.

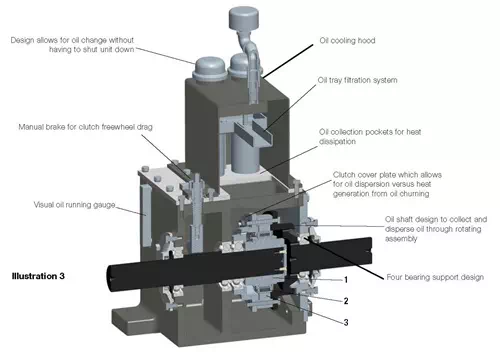

Housings are of rugged, cast construction with liberal cooling areas to permit dissipation of heat which may be generated during high speed freewheeling operation. The stationary housing also provides a large oil reservoir with many times the oil capacity of an ordinary freewheeling clutch.

Provision is made against unnecessary churning of the oil. This is done by ample reservoirs to hold the excess oil volume out of the rotating clutch chamber during high speed operation. The oil, caught in the reservoirs, is cooled and is then recirculated in controlled volume from the bottom of these reservoirs.

In addition to permitting high shaft speeds and continuous uninterrupted operation, the following design features are equally important in certain applications.

Operation On Other Than The Horizontal Plane

Cement and other pyro kilns have drive systems that are not horizontal. Under these conditions a standard freewheeling clutch coupling might tend to lose its lubricant while the shafts were not in a horizontal plane.

Maintenance

CECON Clutches Type CEUS are continuously self-lubricated without the use of pumps or external piping. The selfcirculating lubricant is also self-filtering by continuous gravity flow through 100-mesh stainless steel filter-strainers.

Means are provided for easy renewal of the filtering elements. The only dependence on the human element is that of visually checking oil level, occasional sampling for oil purity and cleaning of filter strainers, none of which requires shut-down of the equipment. A breather-filter is provided to compensate for barometric and temperature changes.

Oil Sampling

A drain valve on the easiest-to-reach side of the CECON Clutch permits sampling of the lubricant to help detect the presence of any contaminant and draining if necessary.

Free Rotation

The cylindrical rollers used in all Marland Clutch products are free to rotate in their individual pockets during freewheeling permitting the load to be engaged and re-engaged on any part of the roller circumference and cylinder surface.

Lower Stress

When roller and cam are engaged under compressive loading, the load is uniformly distributed over a large zone of contact with consequently lower stresses to result in more durable, efficient operation.

Accurate Dimensions

Cylindrical rollers are easy to produce and reproduce to precision dimension limits which are readily checked with micrometers, go-no-go gauges, or if necessary, with the extreme closeness of light band inspection.

อุปกรณ์ป้องกันสายพานไหลกลับ / Backstops

CEBMAG Backstops

For some time, the trend in the cement and other pyro-processing industries has been toward larger and more efficient kilns. Since these kilns operate 24 hours per day, month after month, it has been important to conserve power and avoid down time as much as possible.

The high degree of efficiency in the mechanical power transmission that has evolved also means that the kiln can roll back due to the large off-center mass of material in the kiln when power failure occurs or at any time the main drive is shut down. Uncontrolled rollback carries the danger of centrifugal explosion of the main drive components since they may be oversped to many times the normal forward speed.

Another consideration to be made during main drive shutdown is the prevention of kiln distortion due to the high temperatures. An emergency drive can be utilized to provide forward rotation at a reduced speed, both to prevent distortion and also to empty the contents of the kiln before it becomes impacted to the lining.

Marland CECON clutches and CEBMAG backstops provide automatic, remote emergency operation in case of main electric power failure. Their use provides for controlled reversal of the kiln and automatic changeover to emergency drive for forward rotation reduced speed.